焊接冶金学(第3版) Welding Metallurgy , Third Edition 英文原版 Sindo Kou Wiley

| 运费: | ¥ 0.00-16.00 |

| 库存: | 1 件 |

商品详情

Welding Metallurgy

基本信息

Format:Hardback 688 pages

Publisher:John Wiley and Sons Ltd

Imprint:Wiley-Blackwell

Edition:3rd Edition

ISBN:9781119524816

Published: 26 Nov 2020

Classifications:Civil engineering, surveying & building

Readership:Professional & Vocational

Weight:1762g

Dimensions:263 x 209 x 36 (mm)

Pub. Country:United States

页面参数仅供参考,具体以实物为准

书籍简介

《焊接冶金学》介绍了近二十年来焊接冶金学的非凡进展。

《焊接冶金学》第三版是目前焊接冶金科学和实践发展中完整的概要。本版本包括固态焊接和熔焊,现在还包括电阻点焊。它在聚变区和热影响区进行重构和扩展。前者包括了全新的章节,关于微观偏析,宏观偏析,韧性-倾斜开裂,和合金抗蠕变,磨损和腐蚀,以及一个新的章节,关于合金凝固。后者现在包括固态焊接冶金。在搅拌摩擦焊和电阻点焊中,部分熔化区扩展为熔析和开裂。增加了关于高电流感兴趣的话题的章节,包括添加剂制造,非相似金属连接,镁合金,和高熵合金和金属基纳米复合材料。

Kou为读者提供了数百篇论文和文章的引证,这将进一步增强读者对这个庞大话题的了解。本科生、研究生、研究人员和机械工程师都将从这一综合资源中获益。

新版包括Kou和同事在以下方面的新理论/新方法:

预测填充金属对熔析开裂的影响

预测凝固开裂敏感性的指标和解析方程

对凝固裂纹和填充金属效应的敏感性试验

焊接过程中的液态金属淬火

不锈钢抗凝固开裂和韧性浸渍开裂的机理研究

机制的宏观偏析

铝镁填充金属的飞溅机理

异种金属搅拌摩擦焊熔析开裂

焊缝熔池表面流动引起的变形和振荡及波纹的形成

多组分多相扩散连接

对于学生、研究人员和工程师来说,寇的焊接冶金技术在全世界都是不可或缺的资源。这个新的第三版也不例外。

Discover the extraordinary progress that welding metallurgy has experienced over the last two decades

Welding Metallurgy, Third Edition is the only complete compendium of recent, and not-so-recent, developments in the science and practice of welding metallurgy. Written by Dr. Sindo Kou, this edition covers solid-state welding as well as fusion welding, which now also includes resistance spot welding. It restructures and expands sections on Fusion Zones and Heat-Affected Zones. The former now includes entirely new chapters on microsegregation, macrosegregation, ductility-dip cracking, and alloys resistant to creep, wear and corrosion, as well as a new section on ternary-alloy solidification. The latter now includes metallurgy of solid-state welding. Partially Melted Zones are expanded to include liquation and cracking in friction stir welding and resistance spot welding. New chapters on topics of high current interest are added, including additive manufacturing, dissimilar-metal joining, magnesium alloys, and high-entropy alloys and metal-matrix nanocomposites.

Dr. Kou provides the reader with hundreds of citations to papers and articles that will further enhance the reader's knowledge of this voluminous topic. Undergraduate students, graduate students, researchers and mechanical engineers will all benefit spectacularly from this comprehensive resource.

The new edition includes new theories/methods of Kou and coworkers regarding:

Predicting the effect of filler metals on liquation cracking

An index and analytical equations for predicting susceptibility to solidification cracking

A test for susceptibility to solidification cracking and filler-metal effect

Liquid-metal quenching during welding

Mechanisms of resistance of stainless steels to solidification cracking and ductility-dip cracking

Mechanisms of macrosegregation

Mechanisms of spatter of aluminum and magnesium filler metals,

Liquation and cracking in dissimilar-metal friction stir welding,

Flow-induced deformation and oscillation of weld-pool surface and ripple formation

Multicomponent/multiphase diffusion bonding

Dr. Kou's Welding Metallurgy has been used the world over as an indispensable resource for students, researchers, and engineers alike. This new Third Edition is no exception.

目录

Part I Introduction

1. Welding Processes

1.1 Overview

1.2 Gas Welding

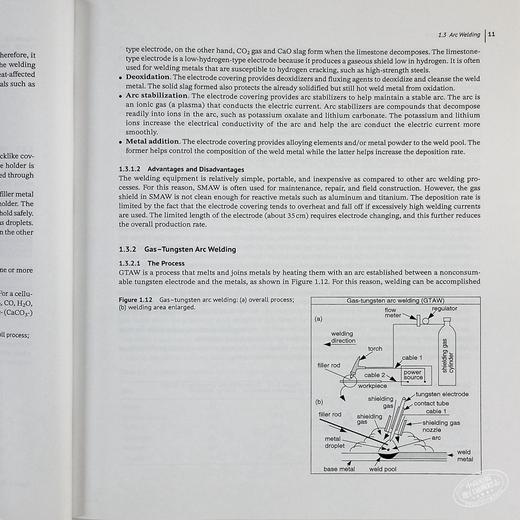

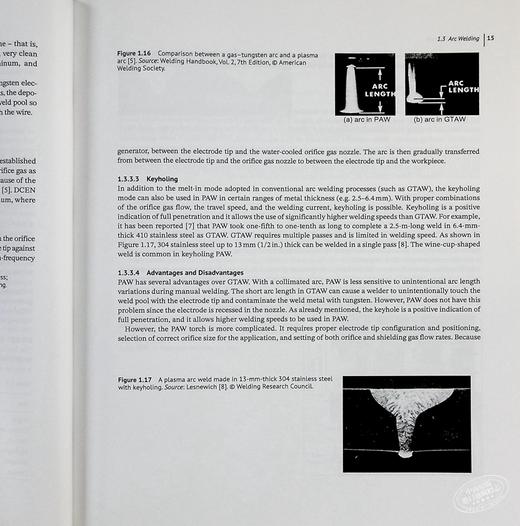

1.3 Arc Welding

1.4 High Energy Beam Welding

1.5 Resistance Spot Welding

1.6 Solid State Welding

Examples

References

Further Reading

Problems

2. Heat Flow

2.1 Heat Sources

2.2 Heat Flow in Fusion Welding

2.3 Effect of Fusion Welding Parameters

2.4 Weld Thermal Insulator

Examples

References

Further Reading

Problems

3. Fluid Flow

3.1 Fluid Flow in Arcs

3.2 Effect of Metal Vapor on Arcs

3.3 Arc Power- and Current-Density Distributions

3.4 Fluid Flow in Weld Pools

3.5 Flow Oscillation and Ripple Formation

3.6Active Flux GTAW

Examples

References

Further Reading

Problems

4. Mass Transfer

4.1 Convective Mass Transfer in Weld Pools

4.2 Evaporation of Volatile Solutes

4.3 Filler-Metal-Drop Explosion and Spatter

4.4 Spatter in GMAW of Magnesium

4.5 Diffusion Bonding

Examples

References

Further Reading

Problems

5. Chemical Reactions in Welding

5.1 Overview

5.2 Gas-Metal Reactions

5.3 Slag-Metal Reactions

Examples

References

Further Reading

Problems

6. Residual Stresses, Distortion and Fatigue

6.1 Residual Stresses

6.2 Distortion

6.3 Fatigue

Examples

References

Further Reading

Problems

Part II The Fusion Zone

7. Introduction to Solidification

7.1 Solute Redistribution during Solidification

7.2 Constitutional Supercooling

7.3 Solidification Modes

7.4 Microsegregation Caused by Solute Redistribution

7.5 Secondary Dendrite Arm Spacing

7.6 Effect of Dendrite Tip Undercooling

7.7 Effect of Growth Rate

7.8 Solidification of Ternary Alloys

Examples

References

Further Reading

Problems

8. Solidification Modes

8.1 Solidification Modes of Weld Metal

8.2 Dendrite Spacing and Cell Spacing

8.3 Effect of Welding Parameters

8.4 Refining Microstructure within Grains

Examples

References

Further Reading

Problems

9. Nucleation and Growth of Grains

9.1 Epitaxial Growth at Fusion Line

9.2 Non-Epitaxial Growth at Fusion Line

9.3 Growth of Columnar Grains

9.4 Effect of Welding Parameters on Columnar Grains

9.5 Control of Columnar Grains

9.6 Nucleation Mechanisms of Equiaxed Grains

9.7 Grain Refining

9.8 Identifying Grain Refining Mechanisms

9.9 Grain-Boundary Migration

Examples

References

Further Reading

Problems

10. Microsegregation

10.1 Case III Solute Redistribution and Microsegregation

10.2 Effect of Travel Speed on Microsegregation

10.3 Effect of Primary Solidification Phase on Microsegregation

10.4 Effect of Maximum Solid Solubility on Microsegregation

Examples

References

Further Reading

Problems

11. Macrosegregation

11.1 Macrosegregation in Fusion Zone

11.2 Quick Freezing of One Liquid Metal in Another

11.3 Macrosegregation in Dissimilar-Filler Welds

11.4 Macrosegregation in Dissimilar-Metal Welds

11.5 Reduction of Macrosegregation

11.6 Macrosegregation in Multiple-Pass Welds

Examples

References

Further Reading

Problems

12. Some Alloy-Specific Microstructures and Properties

12.1 Austenitic Stainless Steels

12.2 Low-Carbon, Low-Alloy Steels

12.3 Ultralow Carbon Bainitic Steels

12.4 Creep Resistant Steels

12.5 Hardfacing of Steels

Examples

References

Further Reading

Problems

13. Solidification Cracking

13.1 Characteristics of Solidification Cracking

13.2 Theories of Solidification Cracking

13.3 Analytical Equations for Crack Susceptibility

13.4 Solidification Cracking Tests

13.5 Solidification Cracking of Stainless Steels

13.6 Factors Affecting Solidification Cracking

13.7 Reducing Solidification Cracking

Examples

References

Further Reading

Problems

14. Ductility-Dip Cracking

14.1 Characteristics of Ductility-Dip Cracking

14.2 Theories of Ductility-Dip Cracking

14.3 Test Methods

14.4 Ductility-Dip Cracking of Ni-Base Alloys

14.5 Ductility-Dip Cracking of Stainless Steels

Examples

References

Further Reading

Problems

Part III Partially Melted Zone

15. Liquation in Partially Melted Zone

15.1 Evidence of Liquation

15.2 Liquation Mechanisms

15.3 Solidification of Grain-Boundary Liquid

15.4 Grain-Boundary Segregation

Examples

References

Further Reading

Problems

16. Liquation Cracking

16.1 Liquation Cracking in Arc Welding

16.2 Liquation Cracking in Resistance Spot Welding

16.3 Liquation Cracking in Friction-Stir Welding

16.4 Liquation Cracking in Dissimilar-Metal Friction-Stir Welding

Examples

References

Further Reading

Problems

Part IV Heat-Affected-Zone

17. Introduction to Solid-State Transformations

17.1 Work-Hardened Materials

17.2 Heat-Treatable Al Alloys

17.3 Heat-Treatable Ni-base Alloys

17.4 Steels

17.5 Stainless Steels

Examples

References

Further Reading

Problems

18. Heat-Affected-Zone Degradation of Mechanical Properties

18.1 Grain Coarsening

18.2 Recrystallization and Grain Growth

18.3 Overaging in Al Alloys

18.4 Dissolution of Precipitates in Ni-Base Alloys

18.5 Martensite Tempering in Dual-Phase Steels

Examples

References

Further Reading

Problems

19. Heat-Affected-Zone Cracking

19.1 Hydrogen Cracking in Steels

19.2 Lamellar Tearing in Steels

19.3 Stress-Relief Cracking in Steels

19.4 Type-IV Cracking in Grade 91 Steel

19.5 Strain-Age Cracking in Ni-base Alloys

Examples

References

Further Reading

Problems

20. Heat-Affected-Zone Corrosion

20.1 Weld Decay of Stainless Steels

20.2 Weld Decay of Ni-base alloys

20.3 Knife-Line Attack of Stainless Steels

20.4 Sensitization of Ferritic Stainless Steels

20.5 Stress Corrosion Cracking of Austenitic Stainless Steels

Examples

References

Further Reading

Problems

Part V Special Topics

21. Additive Manufacturing

21.1 Heat and Fluid Flow

21.2 Residual Stress and Distortion

21.3 Lack of fusion and porosity

21.4 Grain Structure

21.5 Solidification Cracking

21.6 Liquation Cracking

21.7 Graded Transition Joints

Examples

References

Further Reading

Problems

22. Dissimilar-Metal Joining

22.1 Arc and Laser Joining

22.2 Resistance Spot Welding

22.2 Friction Stir Welding

22.3 Solid-State Welding

Examples

References

Further Reading

Problems

23. Welding of Magnesium Alloys

23.1 Spatter

23.2 Porosity

23.3 Internal Oxide Films

23.4 High Crowns

Examples

References

Further Reading

Problems

24. Welding of High-Entropy Alloys and Metal-Matrix Nanocomposites

24.1 High Entropy Alloys

24.2 Metal-matrix Nanocomposites

Examples

References

Further Reading

Problems

Index

作者简介

Sindo Kou博士是威斯康星大学材料科学与工程系教授,前任系主任。他毕业于麻省理工学院,获得冶金学博士学位。他是美国焊接学会和ASM国际会员。

他获得了美国焊接学会(AWS)颁发的威廉·伊尔冈纪念奖(2018)、荣誉会员奖(2016)和康弗·a·亚当斯讲座奖(2012);由国际焊接学会(IIW)颁发的Yoshiaki Arata奖(2017);美国矿物、金属与材料学会(TMS)颁发的2013年布鲁斯·查默斯奖;美国钢铁协会颁发的约翰·奇普曼奖(1980);以及威斯康辛-麦迪逊大学校长杰出教学奖(1999)。技术论文获得Warren F. Savage Memorial Award(4次)、Charles H. Jennings Memorial Award(4次)、William Spraragen Award(3次)、A.F. Davis银牌奖和James F. Lincoln AWS金奖;TMS镁技术最佳论文奖。

Sindo Kou, PhD, is Professor and former Chair of the Department of Materials Science and Engineering at the University of Wisconsin. He graduated from MIT with a doctorate in metallurgy. He is a Fellow of American Welding Society and ASM International.

He received the William Irrgang Memorial Award (2018), the Honorary Membership Award (2016), and the Comfort A. Adams Lecture Award (2012) from the American Welding Society (AWS); the Yoshiaki Arata Award (2017) from the International Institute of Welding (IIW); the Bruce Chalmers Award (2013) from The Minerals, Metals & Materials Society (TMS); the John Chipman Award (1980) from the Iron and Steel Society of AIME; and Chancellor's Award for Distinguished Teaching (1999) from the University of Wisconsin-Madison. His technical papers won the Warren F. Savage Memorial Award (4 times), Charles H. Jennings Memorial Award (4 times), William Spraragen Award (3 times), A.F. Davis Silver Medal Award, and James F. Lincoln Gold Medal of AWS; and the Magnesium Technology Best Paper Award of TMS.

- 中商进口商城 (微信公众号认证)

- 中商进口商城中华商务贸易有限公司所运营的英美日韩港台原版图书销售平台,旨在向内地读者介绍、普及、引进最新最有价值的国外和港台图书和资讯。

- 扫描二维码,访问我们的微信店铺

- 随时随地的购物、客服咨询、查询订单和物流...