商品详情

定价:28.0

ISBN:9787122107220

作者:曹同玉 冯连芳 张菊华 主编

版次:2

出版时间:2011-06

内容提要:

基本信息

书名:高分子材料工程专业英语(第2版)

原价:28.00元

作者:

出版社:化学工业出版社

出版日期:2011年6月1日

ISBN:9787122107220

字数:

页码:200

版次:第2版

装帧:平装

开本:16

重量:481 g

正文语种:英语

编辑推荐

《高分子材料工程专业英语(第2版)》是大学英语专业阅读教材编写委员会组织编写的。

媒体推荐

内容提要

《高分子材料工程专业英语(第2版)》是《高分子材料工程专业英语》的第二版,是“大学英语专业阅读教材编写委员会”组织编写的高等学校化工专业英语系列教材之一。全书共分32课,包括高分子化学、高分子物理、聚合反应工程、聚合物性能、成型加工及应用,以及高分子材料的实验、研制与生产等多方面的内容。每课均由课文、重点词汇(单词、音标及解释)、词组、课文注释、练习、阅读材料等部分组成。

《高分子材料工程专业英语(第2版)》主要作为全国各高等院校高分子专业英语教材,也可作为从事高分子合成、成型加工、研制及应用工作的科技人员、教师及研究生提高专业英语水平的参考用书。

目录

PART APolymer Chemistry and Physics1

UNIT 1What Are Polymers?1

UNIT 2Chain Polymerization7

UNIT 3StepGrowth Polymerization13

UNIT 4Ionic Polymerization19

UNIT 5Introduction to Living Radical Polymerization25

UNIT 6Molecular Weight and Its Distributions of Polymers30

UNIT 7Polymer Solution36

UNIT 8Morphology of Solid Polymers42

UNIT 9Structure and Properties of Polymers48

UNIT 10Glass Transition Temperature54

UNIT 11Functional Polymers59

UNIT 12Preparations of Amino Resins in Laboratory65PART BPolymerization Reaction Engineering72

UNIT 13Reactor Types72

UNIT 14Bulk Polymerization78

UNIT 15General Description of VC Suspension Polymerization Process83

UNIT 16StyreneButadiene Copolymer88

UNIT 17Heat Transfer Process95

UNIT 18Copolymer Composition Distributions Affected by Micromixing100

UNIT 19Introduction to Modelling of Polymerization Kinetics106

UNIT 20Polymerization Process Instrumentation112

UNIT 21Reactor Scaleup118

UNIT 22Unipol Process for Polyethylene123PART CProcessing,Properties and Applications of Polymer Material129

UNIT 23Polymer Processing129

UNIT 24Mechanical Properties of Polymers135

UNIT 25Thermal Properties of Polymers139

UNIT 26Polymer Melts143

UNIT 27Processing and Fabrication of Thermoplastics147

UNIT 28General Aspects of Polymer Degradation153

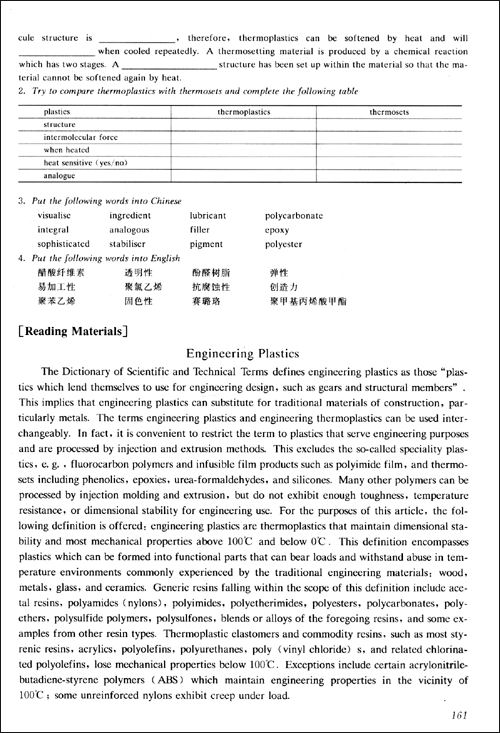

UNIT 29Synthetic Plastics158

UNIT 30Synthetic Rubber164

UNIT 31Structure of Fiberforming Polymers171

UNIT 32Matching Adhesive to Adherend175APPENDIXES179

Appendix 1聚合物的命名法179

Appendix 2总词汇表188

作者介绍

文摘

版权页:

插图:

Before the temperature is increased again,the stirrer is stopped and another sample of resin is withdrawn,weighed,and titrated.The stirrer is restarted,and the temperature ofthe reaction mixture quickly is raised another 10 degree where it is maintained until the wa-ter-evolution rate perceptibly is diminished.The reaction is completed isothermally at the highest practical temperature.The titration data are more meaningful than the azeotrope data in the later stages of the reaction.A final sample of resin should be titrated before the reaction is halted.

Some formulations cannot be permitted to react to their theoretical endpoint since side reactions cause crosslinking and its consequence-gelation.If the reaction mixture thickens markedly and it begins to ascend the stirrer shaft,additional glycol should be introduced quickly to induce ester-interchange reactions.This action will serve to inhibit the crosslink-ing reaction of the decomposing resin,and will facilitate the removal of the resin from the kettle.Measurements made beyond the gel point are meaningless;the partially gelled resin should be discarded.

When the reaction is concluded,the distillation trap and the nitrogen-inlet tube are re-moved.Before proceeding further,be sure to put on the asbestos gloves.The thermocouple and the stirrer may be wiped clean with a cotton swab once they have been removed.When the resin mixture has cooled below 200℃,it maY be poured into a heavy-walled glass jar placed inside of a protective metal container.The conventional 8screwcap laboratory jars are excellent for this purpose;they have good resistance to thermal shock.

The transfer of the resin into the jar is best accomplished by inverting the resin kettle while it is still secured in its mechanical mount and by permitting the kettle to drain in this position.The drained kettle also may be cleaned with cotton swabs.

The decalin-polyester mixture will separate upon cooling to room temperature.A characteristic resin sample will be obtained merely by decanting the supernatant decalin layer.

序言

目录:

PART A Polymer Chemistry and Physics UNIT 1 What Are Polymers? UNIT 2 Chain Polymerization UNIT 3 Step?Growth Polymerization UNIT 4 Ionic Polymerization UNIT 5 Introduction to Living Radical Polymerization UNIT 6 Molecular Weight and Its Distributions ofPolymers UNIT 7 Polymer Solution UNIT 8 Morphology of Solid Polymers UNIT 9 Structure and Properties of Polymers UNIT 10 Glass Transition Temperature UNIT 11 Functional Polymers UNIT 12 Preparations of Amino Resins in Laboratory PART B Polymerization Reaction Engineering

PART A Polymer Chemistry and Physics

UNIT 1 What Are Polymers?

UNIT 2 Chain Polymerization

UNIT 3 Step?Growth Polymerization

UNIT 4 Ionic Polymerization

UNIT 5 Introduction to Living Radical Polymerization

UNIT 6 Molecular Weight and Its Distributions of Polymers

UNIT 7 Polymer Solution

UNIT 8 Morphology of Solid Polymers

UNIT 9 Structure and Properties of Polymers

UNIT 10 Glass Transition Temperature

UNIT 11 Functional Polymers

UNIT 12 Preparations of Amino Resins in Laboratory

PART B Polymerization Reaction Engineering

UNIT 13 Reactor Types

UNIT 14 Bulk Polymerization

UNIT 15 General Description of VC Suspension Polymerization Process

UNIT 16 Styrene?Butadiene Copolymer

UNIT 17 Heat Transfer Process

UNIT 18 Copolymer Composition Distributions Affected by Micromixing

UNIT 19 Introduction to Modelling of Polymerization Kinetics

UNIT 20 Polymerization Process Instrumentation

UNIT 21 Reactor Scale?up

UNIT 22 Unipol Process for Polyethylene

PART C Processing,Properties and Applications of Polymer Material

UNIT 23 Polymer Processing

UNIT 24 Mechanical Properties of Polymers

UNIT 25 Thermal Properties of Polymers

UNIT 26 Polymer Melts

UNIT 27 Processing and Fabrication of Thermoplastics

UNIT 28 General Aspects of Polymer Degradation

UNIT 29 Synthetic Plastics

UNIT 30 Synthetic Rubber

UNIT 31 Structure of Fiber?forming Polymers

UNIT 32 Matching Adhesive to Adherend

APPENDIXES

Appendix 1 聚合物的命名法

Appendix 2 总词汇表

显示全部信息

- 化学工业出版社官方旗舰店 (微信公众号认证)

- 扫描二维码,访问我们的微信店铺

- 随时随地的购物、客服咨询、查询订单和物流...