Analyzation and Optimization of Microbrewery System 酿造系统分析与优化 申文静 啤酒酿造过程控制理论啤酒酿造数字化工厂建设

¥90.00

| 运费: | ¥ 3.00-15.00 |

商品详情

书名:Analyzation and Optimization of Microbrewery System(酿造系统分析与优化)

定价:128.0

ISBN:9787122371539

作者:(中)申文静(Wenjing,Shen)、(德)约翰尼斯·赫尔曼(Johannes,Herrmann)、(德)奥利弗·格里尔(Oli

版次:第1版

出版时间:2020-07

内容提要:

作者简介:

申文静,深圳技术大学中德智能制造学院教师 ,香港城市大学博士毕业,曾获香港政府全额奖学金,2018年获深圳市海外高层次C类人才;研究方向为物理建模和参数优化,工业系统参数智能调节应用; 主持并参与了多项国家省级自然科学基金和企业横向课题,研究机电一体化系统集成和设备改造;发表国内外期刊论文十余篇,申报国家发明专利八项,国际PCT专利两项。 与德国雷根斯堡应用技术大学合作,负责筹建“中德啤酒酿造过程控制实验室”,主持教育部协同育人项目“啤酒酿造过程控制数字化工厂”,教研项目“中德过程控制联合实验室教学探索与研究”; 已在实验室指导多名德国留学生进行酿造设备自动化改造。计划初步建立基于LabVIEW平台的啤酒酿造数字化工厂的模型,结合智能传感网络对整个生产过程进行仿真、评估、优化和智能控制。

目录:

1 Introduction and objective 1

2 General explanation of a brewing process 4

2.1 Ingredients 4

2.1.1 Water 4

2.1.2 Malt 5

2.1.3 Hops 5

2.1.4 Yeast 6

2.2 Work steps for the production of beer 6

2.2.1 Grinding of the malt 7

2.2.2 Mashing 7

2.2.3 Lautering 7

2.2.4 Cooking and addition of hops 8

2.2.5 Hot break separation 8

2.2.6 Cooling of the wort 9

2.2.7 Pitching yeast 9

2.2.8 Fermentation 9

2.2.9 Secondary fermentation and storing 9

3 Description of the brewing plant 11

3.1 Controlling and monitoring of the plant 12

3.2 Four-tank system for the production of wort 13

3.2.1 Mash tank 14

3.2.2 Lauter tank 16

3.2.3 Boiling pot 17

3.2.4 Whirlpool 18

3.3 Fermentation and storage 20

3.3.1 Plate heat exchanger, yeast container and ice water tank 20

3.3.2 Fermentation and storage tanks 21

3.4 Additional components of the brewing plant 22

3.4.1 Cleaning of the fermentation tanks 22

3.4.2 Grinding of the malt 23

3.4.3 Storage of the malt and the hops 24

3.4.4 Production of steam 24

4 Collection of data from the mash tank 26

4.1 Geometrical dimensions 26

4.2 Materials and wall thicknesses 30

4.3 Stirring unit 30

4.4 Heat transfer from the steam to the brewing water 31

4.4.1 Experiments for the distinction of the energy supply by observation of the vapor pressure 32

4.4.2 Calculation of USB 33

4.5 Total heat transmission coeff?icient 35

4.5.1 Experiments for the measurement of the wall temperatures 37

4.5.2 Calculation of ho 39

4.5.3 Calculation of hi 42

4.5.4 Calculation of the total heat transmission coeff?icient 46

4.6 Volume flow of tap water 47

4.7 Summary of the values for the mash tank 48

5 Creation of a flow sheet of the brewing plant 49

5.1 Existing f?low sheet 50

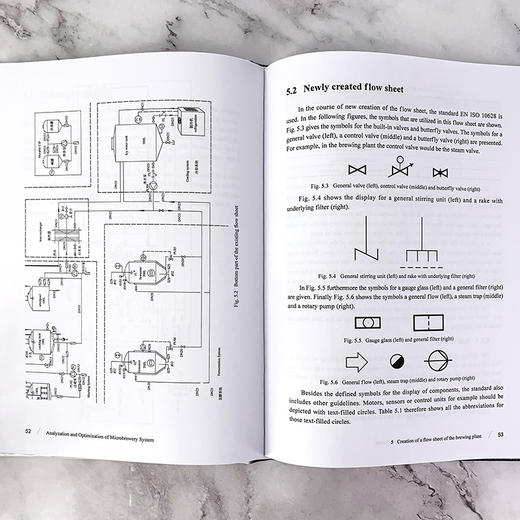

5.2 Newly created f?low sheet 53

5.2.1 Malt milling 54

5.2.2 Steam production 54

5.2.3 Production of wort 58

5.2.4 Cooling of the wort and addition of yeast 59

5.2.5 Cooling water supply 60

5.2.6 Fermentation and storage 60

6 Description of the brewing process 62

6.1 Operation of the plant 62

6.2 Cleaning before the brewing process 65

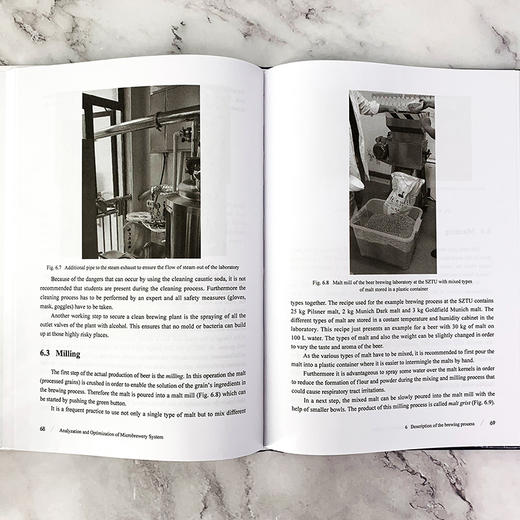

6.3 Milling 68

6.4 Mashing 70

6.5 Lautering 73

6.6 Cooking 74

6.7 Hot break separation 76

6.8 Cooling 76

6.9 Pitching yeast 77

6.10 Fermentation 79

6.11 Secondary fermentation and storing the beer 80

6.12 Cleaning after the brewing process 81

7 Control of the brewing plant 84

7.1 Fundamentals of programmable logic controllers 84

7.2 S7-200 SMART 85

7.2.1 CPU S7-200 SMART SR40/ST60 85

7.2.2 EM AM06 86

7.2.3 EM AR04/AR02 86

7.3 Switch cabinet with basic functions 87

7.4 Switch cabinet for temperature control 89

8 Basics of network technology 92

8.1 Industrial Ethernet 92

8.2 OPC Foundation 94

8.3 OPC Technology 95

8.3.1 OPC Classic 95

8.3.2 OPC Unif?ied Architecture 97

9 Implementation of a LabVIEW program 99

9.1 Program interface 99

9.2 OPC Server software 100

9.2.1 Shared Variable Engine 100

9.2.2 DSC module 101

9.2.3 NI OPC Server 101

9.2.4 OPC tags 102

10 LabVIEW program—brewing plant control 106

10.1 Graphical user interface 106

10.2 Advanced Features 108

10.2.1 Dual control of the system via LabVIEW and control panel 109

10.2.2 Data Dashboard 111

11 Current temperature control system 113

11.1 Existing controller quality 113

11.2 Modif?ication of control valves and temperature sensor 115

12 Simulation of the mash tank’s temperature control 117

12.1 Controller design 117

12.1.1 Identif?ication of parameters 117

12.1.2 Basics of PID controlling 120

12.1.3 Fundamentals of Fuzzy control 123

12.1.4 PID controller design 128

12.1.5 Fuzzy controller design 130

12.2 Build-up of the simulation in LabVIEW 133

12.2.1 Representation of the controlled system 133

12.2.2 Program structure and functionality 134

12.2.3 Optimization of the simulated controllers 142

13 Implementation of the control system 146

13.1 Operation of the brewing plant 146

13.2 Experiments on the real system 147

13.2.1 Experiments with PI controller 148

13.2.2 Experiments with fuzzy controller 148

13.3 Comparison between simulation and reality 152

13.4 Further investigations 152

References 155

Appendix A 157

Appendix B 159

Figures 160

Tables 167

定价:128.0

ISBN:9787122371539

作者:(中)申文静(Wenjing,Shen)、(德)约翰尼斯·赫尔曼(Johannes,Herrmann)、(德)奥利弗·格里尔(Oli

版次:第1版

出版时间:2020-07

内容提要:

本书以德国啤酒酿造过程为背景,内容包括啤酒酿造系统分析、LabVIEW与OPC协议、过程控制理论、酿造过程温度控制等内容,初步建立基于LabVIEW平台的啤酒酿造数字化工厂的模型,结合智能传感网络对整个生产过程进行仿真、评估、优化和智能控制。 本书可供食品工程、机电、工业技术等行业的科学研究与技术开发人员参考,也可供相关专业大专院校师生阅读。

作者简介:

申文静,深圳技术大学中德智能制造学院教师 ,香港城市大学博士毕业,曾获香港政府全额奖学金,2018年获深圳市海外高层次C类人才;研究方向为物理建模和参数优化,工业系统参数智能调节应用; 主持并参与了多项国家省级自然科学基金和企业横向课题,研究机电一体化系统集成和设备改造;发表国内外期刊论文十余篇,申报国家发明专利八项,国际PCT专利两项。 与德国雷根斯堡应用技术大学合作,负责筹建“中德啤酒酿造过程控制实验室”,主持教育部协同育人项目“啤酒酿造过程控制数字化工厂”,教研项目“中德过程控制联合实验室教学探索与研究”; 已在实验室指导多名德国留学生进行酿造设备自动化改造。计划初步建立基于LabVIEW平台的啤酒酿造数字化工厂的模型,结合智能传感网络对整个生产过程进行仿真、评估、优化和智能控制。

目录:

1 Introduction and objective 1

2 General explanation of a brewing process 4

2.1 Ingredients 4

2.1.1 Water 4

2.1.2 Malt 5

2.1.3 Hops 5

2.1.4 Yeast 6

2.2 Work steps for the production of beer 6

2.2.1 Grinding of the malt 7

2.2.2 Mashing 7

2.2.3 Lautering 7

2.2.4 Cooking and addition of hops 8

2.2.5 Hot break separation 8

2.2.6 Cooling of the wort 9

2.2.7 Pitching yeast 9

2.2.8 Fermentation 9

2.2.9 Secondary fermentation and storing 9

3 Description of the brewing plant 11

3.1 Controlling and monitoring of the plant 12

3.2 Four-tank system for the production of wort 13

3.2.1 Mash tank 14

3.2.2 Lauter tank 16

3.2.3 Boiling pot 17

3.2.4 Whirlpool 18

3.3 Fermentation and storage 20

3.3.1 Plate heat exchanger, yeast container and ice water tank 20

3.3.2 Fermentation and storage tanks 21

3.4 Additional components of the brewing plant 22

3.4.1 Cleaning of the fermentation tanks 22

3.4.2 Grinding of the malt 23

3.4.3 Storage of the malt and the hops 24

3.4.4 Production of steam 24

4 Collection of data from the mash tank 26

4.1 Geometrical dimensions 26

4.2 Materials and wall thicknesses 30

4.3 Stirring unit 30

4.4 Heat transfer from the steam to the brewing water 31

4.4.1 Experiments for the distinction of the energy supply by observation of the vapor pressure 32

4.4.2 Calculation of USB 33

4.5 Total heat transmission coeff?icient 35

4.5.1 Experiments for the measurement of the wall temperatures 37

4.5.2 Calculation of ho 39

4.5.3 Calculation of hi 42

4.5.4 Calculation of the total heat transmission coeff?icient 46

4.6 Volume flow of tap water 47

4.7 Summary of the values for the mash tank 48

5 Creation of a flow sheet of the brewing plant 49

5.1 Existing f?low sheet 50

5.2 Newly created f?low sheet 53

5.2.1 Malt milling 54

5.2.2 Steam production 54

5.2.3 Production of wort 58

5.2.4 Cooling of the wort and addition of yeast 59

5.2.5 Cooling water supply 60

5.2.6 Fermentation and storage 60

6 Description of the brewing process 62

6.1 Operation of the plant 62

6.2 Cleaning before the brewing process 65

6.3 Milling 68

6.4 Mashing 70

6.5 Lautering 73

6.6 Cooking 74

6.7 Hot break separation 76

6.8 Cooling 76

6.9 Pitching yeast 77

6.10 Fermentation 79

6.11 Secondary fermentation and storing the beer 80

6.12 Cleaning after the brewing process 81

7 Control of the brewing plant 84

7.1 Fundamentals of programmable logic controllers 84

7.2 S7-200 SMART 85

7.2.1 CPU S7-200 SMART SR40/ST60 85

7.2.2 EM AM06 86

7.2.3 EM AR04/AR02 86

7.3 Switch cabinet with basic functions 87

7.4 Switch cabinet for temperature control 89

8 Basics of network technology 92

8.1 Industrial Ethernet 92

8.2 OPC Foundation 94

8.3 OPC Technology 95

8.3.1 OPC Classic 95

8.3.2 OPC Unif?ied Architecture 97

9 Implementation of a LabVIEW program 99

9.1 Program interface 99

9.2 OPC Server software 100

9.2.1 Shared Variable Engine 100

9.2.2 DSC module 101

9.2.3 NI OPC Server 101

9.2.4 OPC tags 102

10 LabVIEW program—brewing plant control 106

10.1 Graphical user interface 106

10.2 Advanced Features 108

10.2.1 Dual control of the system via LabVIEW and control panel 109

10.2.2 Data Dashboard 111

11 Current temperature control system 113

11.1 Existing controller quality 113

11.2 Modif?ication of control valves and temperature sensor 115

12 Simulation of the mash tank’s temperature control 117

12.1 Controller design 117

12.1.1 Identif?ication of parameters 117

12.1.2 Basics of PID controlling 120

12.1.3 Fundamentals of Fuzzy control 123

12.1.4 PID controller design 128

12.1.5 Fuzzy controller design 130

12.2 Build-up of the simulation in LabVIEW 133

12.2.1 Representation of the controlled system 133

12.2.2 Program structure and functionality 134

12.2.3 Optimization of the simulated controllers 142

13 Implementation of the control system 146

13.1 Operation of the brewing plant 146

13.2 Experiments on the real system 147

13.2.1 Experiments with PI controller 148

13.2.2 Experiments with fuzzy controller 148

13.3 Comparison between simulation and reality 152

13.4 Further investigations 152

References 155

Appendix A 157

Appendix B 159

Figures 160

Tables 167

- 化学工业出版社官方旗舰店 (微信公众号认证)

- 扫描二维码,访问我们的微信店铺

- 随时随地的购物、客服咨询、查询订单和物流...